Water treatment in the energy sector: enemies of thermal power plants, water treatment systems

To date, water treatment in the energy sector remains an important issue in the industry. Water is the main source at TPPs, including TPPs, which are subject to increased requirements. Our country is located in a cold climate zone, severe frosts occur in winter. Therefore, thermal power plants are an integral part of a comfortable life for people. Thermal power plants, steam and gas boilers suffer from hard water, which disables expensive equipment. For a clearer understanding, we will deal with the principles of operation of the CHP.

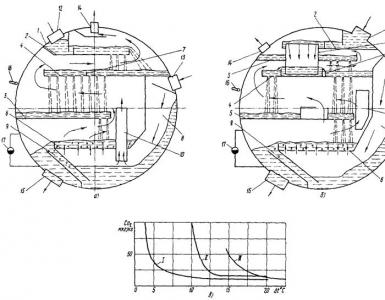

The principle of operation of the CHP

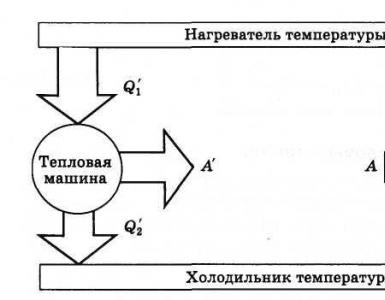

CHP (thermal power main) is considered a type of thermal power plant. It generates electrical energy and is a source of heat in the heat supply system. From the CHP, hot water and steam are supplied to people's homes and industrial enterprises.

The principle of its operation is similar to a condensing power plant. There is only one important difference: part of the heat can be sent to other needs. The amount of selected steam is regulated at the enterprise. The thermal turbine determines the way energy is harvested. The separated steam is collected in the heaters. The energy is then transferred to the water, which moves through the system. It transfers energy to peak water heating boiler houses and heat points.

Water treatment can have two load curves:

- thermal;

- electric.

If the main load is thermal, then the electrical one obeys it. If an electrical load is installed, then the thermal load may even be absent. A combined load option is possible, which makes it possible to use the residual heat for heating. Such CHP plants have an efficiency of 80%.

During the construction of the CHP, the absence of heat transfer over long distances is taken into account. Therefore, it is located in the city.

CHP problems

The main drawback of energy production at thermal power plants is the formation of a solid precipitate that precipitates when water is heated. To clean the system, it will be necessary to stop and dismantle all equipment. Scale is removed at all turns and in narrow openings. In addition to scale, well-coordinated work will be hampered by corrosion, bacteria, and so on.

Scale

The main disadvantage of scale is a decrease in thermal conductivity. Even its insignificant layer leads to high fuel consumption. Permanent descaling is not possible. Only monthly cleaning is allowed, which incurs losses from downtime and damages the surface of the equipment. The amount of fuel consumed will increase, and the equipment will fail faster.

How to determine when to clean up? The equipment will report itself: the overheating protection systems will work. If scale is not removed, heat exchangers and boilers will not work in the future, fistulas will form or an explosion will occur. All expensive equipment will fail without the ability to restore it.

Corrosion

The main cause of corrosion is oxygen. Circulating water should have it at a minimum level - 0.02 mg / l. If there is enough oxygen, then the likelihood of corrosion on the surface will increase with the increase in the amount of salts, especially sulfates and chlorides.

Large CHP plants have deaerator installations. In small installations, corrective chemicals are used. The pH value of the water should be in the range of 9.5-10.0. With an increase in pH, the solubility of magnetite decreases. It is especially important if brass or copper parts are present in the system.

Plastic is a source of local oxygen release. Modern systems try to avoid flexible plastic pipes or create special oxygen barriers.

bacteria

Bacteria affect the quality of the water used and form some types of corrosion (bacteria on metal and sulfate reducing bacteria). Signs of bacterial growth:

- specific smell of circulating water;

- deviation of the content of chemicals during dosing;

- corrosion of copper and brass components, as well as batteries.

Bacteria come with dirt from the soil or during repairs. The systems and the lower part of the battery have favorable conditions for their growth. Disinfection is carried out with a complete shutdown of the system.

Water treatment for CHP

Water treatment in the energy sector will help to cope with these problems. Thermal power plants install a lot of filters. The main task is to find the optimal combination of different filters. The outlet water must be softened and demineralised.

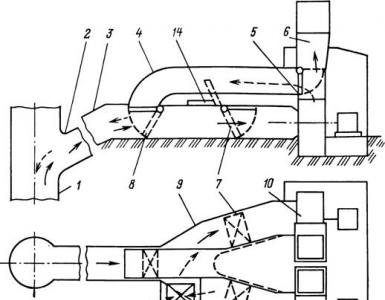

Ion exchange plant

The most common filter It is a tall cylindrical tank with an additional regeneration tank for the filter. The round-the-clock operation of the CHP requires an ion exchange plant with several stages and filters. Each of them has its own recovery tank. The whole system has a common controller (control unit). It monitors the operation parameters of each filter: the amount of water, cleaning speed, cleaning time. The controller does not pass water through filters with full cartridges, but sends it to others. Dirty cartridges are removed and sent to the remanufacturing tank.

The cartridge is initially filled with low sodium resin. With the passage of hard water, chemical reactions occur: strong salts are replaced by weak sodium. Over time, hardness salts accumulate in the cartridge - it should be regenerated.

Salts of a high degree are dissolved in the recovery tank. A highly saturated salt solution (more than 8-10%) comes out, which removes hardness salts from the cartridge. Heavily salted waste is additionally cleaned, and then disposed of by special permission.

The advantage of the installation is the high speed of cleaning. Disadvantages include costly plant maintenance, high cost of salt tablets, and disposal costs.

Electromagnetic water softener

It is also common in CHP. The main elements of the system are:

- strong permanent magnets made of rare earth metals;

- pay;

- electrical processor.

These elements create a strong electromagnetic field. On opposite sides, the device has wound wiring along which waves travel. Each wire is wound more than 7 times on the pipe. During operation, make sure that water does not come into contact with the wiring. The ends of the wires are insulated.

Water passes through the pipe and is irradiated with electromagnetic waves. Hardness salts are transformed into sharp needles, which are inconvenient to “stick” to the equipment surface due to the small contact area. Additionally, needles qualitatively and finely clean the surface of old plaque.

Main advantages:

- self-service;

- no need to care;

- service life of more than 25 years;

- no additional costs.

The electromagnetic softener works with all surfaces. The basis of the installation is installation on a clean section of the pipeline.

Reverse osmosis

In the production of make-up water, a reverse osmosis system is indispensable. She is the only one who can purify water by 100%. It uses a system of various membranes that provide the necessary characteristics of water. The downside is the lack of the possibility of independent use. The reverse osmosis installation must be supplemented with water softeners, which affects the cost of the system.

Only a complete water treatment and purification system guarantees a 100% result and compensates for the high cost of equipment.

The method of water treatment has a strong influence on the operation of heat supply. The economic indicators of operation and the protective function of the system depend on it. During the construction or planned repair of a CHP, special attention should be paid to water treatment.