Deaerator - what is it? Types, device, principle of operation

Heating boilers are most often made of steel. The water passing through them contains oxygen and carbon dioxide. Both of these elements have an extremely negative effect on the metal structures of the boiler. Constant contact of steel with these gases inevitably leads to its rusting. In order to correct the situation and extend the life of the equipment, a special installation is switched on in boiler rooms - a deaerator. What it is? We will talk about this later in the article.

Definition

A deaerator is a special equipment designed to remove oxygen from the coolant of heating systems by heating the latter with steam. Thus, in addition to the cleaning function, devices of this type also perform thermal. The same deaeration unit can be used to heat and treat both feed and make-up water.

Design features

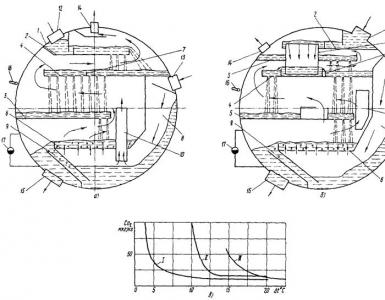

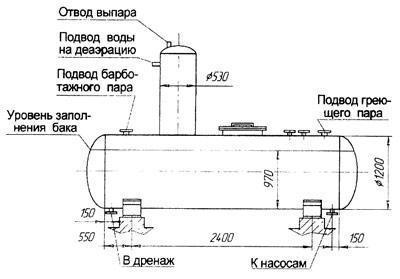

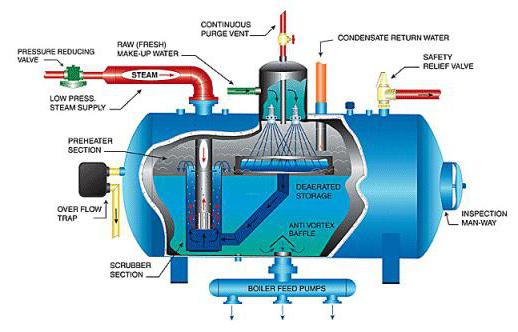

The relative simplicity of design is what distinguishes the deaerator. What is it, we found out. Now let's see how this equipment works. It is a boiler tank deaerator (BDA) with a vertical column (KDA) mounted on it, mounted on supports. An additional element of this type of equipment is a hydraulic system that protects it from overpressure. The column is welded to the tank without a flange - directly.

On the horizontal tank of the deaerator, there are inlet and outlet pipes for connecting the medium supply and discharge lines. Plums are installed below. Another design element is a collection tank designed to collect degassed water. It is located under the bottom of the BDA.

Equipment such as a deaerator, the diagram of which is presented below, usually consists of two water seals. One of them protects the device from any excess of permissible pressure, and the second from dangerous. Also, the design of the hydraulic system of the deaerator includes an expansion tank. The vapors from the deaerator enter a special cooler, which has the form of a horizontal cylinder.

Column design

The column is a cylindrical shell with an elliptical bottom. As on the tank, it has branch pipes for supplying and discharging the medium. Inside the column there are special plates with holes through which water passes. This design allows you to significantly increase the area of contact between the medium and steam, and therefore, to produce heating at maximum speed.

Equipment types

In modern boiler rooms, a water deaerator can be installed:

vacuum;

atmospheric.

In the first type of deaerators, the removal of gases from water is carried out in a vacuum. The design of such installations additionally includes a steam or water jet ejector. The latter type of nodes is most often used in systems with medium or low power boilers. Instead of ejectors, special pumps can be used to create a vacuum. Some disadvantage of equipment such as a vacuum deaerator is that steam must be removed from it forcibly, while it comes out of the atmosphere naturally - under pressure.

In addition to the two types of deaerators considered, high-pressure devices can be installed in boiler rooms. They work at 0.6-0.8 MPa. Sometimes reduced pressure equipment is also included in the thermal scheme of boiler houses.

Scope of use

Where can a deaerator be used? What is it, you now know. Since such a device is designed to degas the working environment, it is mainly used where there is heating equipment made of steel.

Most often, deaerators are used in heating and hot water systems. Boiler rooms with hot water boilers are usually equipped with vacuum-type installations. Also in such schemes atmospheric deaerators can be used. Reduced and increased pressure installations are mainly used in systems that function due to the operation of a steam boiler. The first variety (at 0.025-0.2 MPa) is mounted in not too powerful systems designed for a small number of consumers. used in thermal circuits with boilers supplying a large amount of steam.

Disc deaerator: principle of operation

The gas purification scheme in deaerators is implemented in two stages: jet (in the column) and bubbling (in the tank). In addition, a flooded bubbling device is included in the system. Water is fed into the column, where it is treated with steam. Then it flows into the tank, is kept in it and is discharged back into the system. Steam is initially supplied to the BDA. After ventilation of the internal volume, it enters the column. Passing through the holes of the bubbling tray, the steam heats the water to saturation temperature.

The jet method removes all gases from the water. At the same time, steam condenses. Its residues are mixed with the gas released from the medium and discharged into the cooler. The condensate from the steam is drained into a drainage tank. During the settling of water in the tank, residual small gas bubbles come out of it. Water is drained into a collection tank. Sometimes a horizontal tank is used only for settling. In such installations, both stages of degassing are placed in a column.

Make-up water deaeration

The coolant in the heating system circulates continuously. But its volume over time, as a result of leaks, still gradually decreases. Therefore, make-up water is supplied to the heating system. Like the main one, it must undergo a deaeration process. Initially, water enters the heater, and then passes through chemical filters. Further, as well as nutrient, it enters the deaerator column. Released from flows to the latter directs it to the suction manifold or storage tank.

Chemical deaeration

Thus, the answer to the question of what a boiler room deaerator is is simple. This is equipment designed to boil water with hot steam in order to remove oxygen. However, sometimes gases from the coolant in such installations are not completely removed. In this case, for additional purification, various kinds of reagents designed to bind oxygen can be added to the boiler water. It can be, for example, In this case, for high-quality deaeration of water, its heating is required. Otherwise, chemical reactions will take place too slowly. Also, various kinds of catalysts can be used to accelerate the process of oxygen binding. Sometimes water is also deaerated by passing through a layer of ordinary metal shavings. The latter in this case are rapidly oxidized.

Mounting Features

The deaerator device is not too complicated. However, its installation must be carried out with strict observance of all the required technologies. When installing such equipment, they are primarily guided by the drawings attached to it by the manufacturer and the design of the boiler room. Before installation, the installation is inspected and depreserved. Found defects are eliminated. The actual installation procedure itself includes the following steps:

the tank is mounted on the foundation;

a spillway neck is welded to it;

the lower part of the column is cut to the outer diameter;

the column is installed on the tank (at the same time, the plates fixed inside it must be located strictly horizontally);

the column is welded to the tank;

a vapor cooler and a water seal are installed;

in accordance with the drawings, the lines are connected;

shut-off and control valves are installed;

hydraulic testing of equipment is carried out.

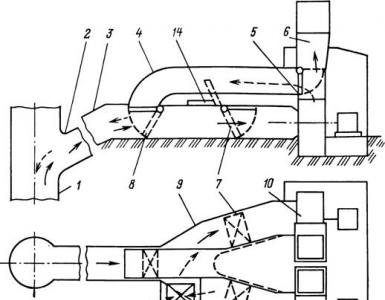

Spray installations

The designs discussed above are called dish-shaped. There are also spray deaerators. Devices of this type are used less often and also represent a large capacity horizontal storage tank. The absence of a column is what distinguishes such a deaerator. Its working principle is also slightly different. Steam in such installations comes from below - from a comb located horizontally in the tank. The container itself is divided into a heating and deaeration zone. The feed water of the boiler enters the first compartment from the atomizer located on top. Here it is heated to the boiling point and enters the deaeration zone, where oxygen is removed from it by steam.

So, that's all that can be said about such a device as a deaerator. What is it, we hope you understand, since we have given a fairly detailed answer to this question. This is the name of the installation that ensures long-term operation of hot water and steam boilers. The choice of the type and methods of installation of this equipment is carried out in accordance with the technical characteristics of the heating equipment and the design of the boiler house.