Lecture 1

In our country, the bulk of the generated electricity (83%) is accounted for by thermal power plants running on organic and nuclear fuel.

The growth in electricity generation is due not only to the introduction of new capacities, but also to the reliability and uninterrupted operation of existing equipment. CHPPs and TPPs currently operate mainly at high and ultra-high parameters, the unit capacities of units at TPPs and CHPPs and, in general, the capacities of power plants are growing. All this increases the requirements for the efficiency and reliability of the operation of the main units of the power plant.

Water and water vapor are heat carriers in the water and steam paths of thermal power plants, thermal power plants and nuclear power plants. For power plants with a block diagram of installation of units, the need to ensure long-term uninterrupted operation is due to the fact that damage or failure of at least one of the elements inevitably causes failure of the entire unit.

Even a short-term emergency downtime of a large unit due to defects in the water regime (long-term operation of a turbine unit with reduced parameters) increases the cost of generated electricity.

One of the factors that determine the importance of the water problem is a significant increase in the specific heat loads of the steam-forming pipes of the boiler unit, which requires a strict limitation of the allowable amount of deposits on the heating surfaces in order to ensure a reliable temperature regime of the metal of these surfaces, and thus the duration of the boiler unit's working time. . To reduce deposits, it is necessary to minimize the amount of impurities entering the water path of the power plant, and first of all, the corrosion products of the main and auxiliary equipment. Also, a systematic introduction of various reagents into the steam-water path of the power plant should be organized, which destroy or limit the effect of the most harmful impurities.

Since high-pressure turbines are very sensitive to blade contamination, it is necessary to improve the quality of the steam in order to avoid power reduction due to drifting of their flow path with deposits.

With an increase in steam parameters, physical and chemical processes of scale formation, steam pollution and metal corrosion are accelerated, which complicates the maintenance of the cleanliness of the internal surfaces of the boiler unit and the flow path of steam turbines, and also makes it difficult to ensure the safety of the metal of boilers, turbines and equipment of the feed water path.

Thus, the treatment of water in a power plant is of great importance. Moreover, the issues of organizing a rational water regime of TPPs should be considered in close connection with their hydrodynamic characteristics, heat transfer processes in individual heat transfer elements and physicochemical processes of generating steam pollution.

Water circulation in the operating cycle of a thermal power plant

Water and water vapor are heat carriers in the water and steam paths of thermal power plants, thermal power plants and nuclear power plants.

When solving the water problem of thermal power plants, it is of great importance that the transition to high and supercritical pressure significantly changes the conditions of vaporization, heat exchange during boiling, hydrodynamics of the steam mixture in the boiler pipes, as well as the properties of the working fluid itself.

For example, with an increase in pressure, the density of water vapor sharply increases, the speed of the steam-water mixture in the steam-generating pipes decreases, the surface tension and viscosity of water decrease, which contributes to the formation of scale and corrosion.

With an increase in the density of water vapor, its ability to dissolve various chemical compounds contained in boiler water increases, which leads to a significant removal of inorganic impurities in the water.

Water at thermal power plants is used:

for the production of steam in boilers, evaporators;

for condensing exhaust steam in condensers of steam turbines and other heat exchangers;

for cooling the blowdown water and smoke exhauster bearings;

as a working heat carrier in heating heating networks and hot water supply networks.

Water vapor obtained in boilers and then used in turbines is condensed or used in the form of steam of reduced parameters at industrial and municipal enterprises for technological processes, heating and ventilation.

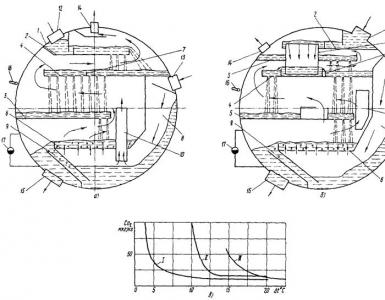

Rice. 1.1. IES scheme:

1 - steam boiler; 2 - steam turbine; 3 - electric generator; 4 - water treatment plant; 5 - capacitor; 6 - condensate pump; 7 - condensate cleaning (BOU); 8 - HDPE; 9 - deaerator; 10 - feed pump; 11 - PVD.

D REF.V. - source water.

D D.V. - additional water is sent to the circuit to make up for the loss of steam and condensate after treatment using physical and chemical cleaning methods.

d T.K. - turbine condensate, contains a small amount of dissolved and suspended impurities - the main component of the feed water.

D V.K. - return condensate from external steam consumers, used after cleaning in the return condensate treatment plant (7) from the introduced contaminants. It is an integral part of feed water.

Dp.c. - feed water is supplied to boilers, steam generators or reactors to replace the evaporated water in these units. It is a mixture of D T . K , D D.V. , D V.K. and condenses in the elements of these aggregates.

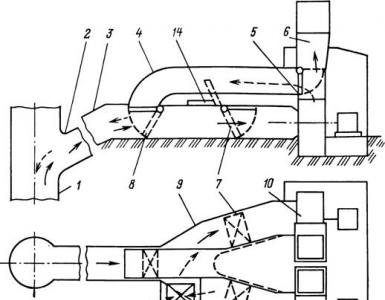

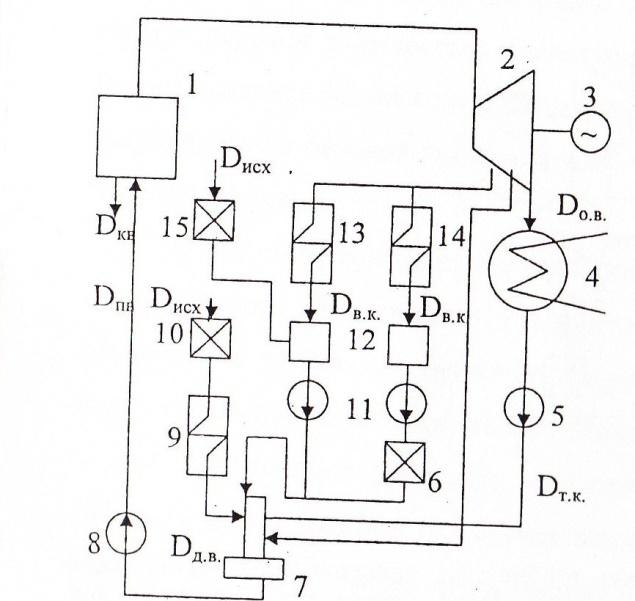

Rice. 1.2. TPP scheme:

1 - steam boiler; 2 - steam turbine; 3 - electric generator; 4 - capacitor; 5 - condensate pump; 6 - unit for purification of return condensate; 7 - deaerator; 8 - feed pump; 9 - additional water heater; 10 - water treatment for feeding boilers; 11 - reverse condensate pumps; 12 - return condensate tanks; 13 - industrial consumer of steam; 14 - industrial consumer of steam; 15 - water treatment for feeding the heating system.

D PR - blowdown water - is discharged from the boiler, steam generator or reactor for cleaning or to drainage to maintain the specified concentrations of impurities in the evaporated (boiler) water. The composition and concentration of impurities in the boiler and blowdown water are the same.

D O.V. - cooling or circulating water, used in the condensers of steam turbines to condense the exhaust steam.

D V.P. - make-up water of the heating network, to make up for losses.