Water heating systems and heat supply

For the normal functioning of technological processes, comfortable stay of a person in the premises, conditions must be provided in accordance with technological and sanitary and hygienic standards. Comfort in the premises is provided by engineering systems of heating, ventilation and air conditioning, heat supply, to which water centralized heat supply systems are carried out.

The heat balance of the premises must be maintained throughout the entire heating season and consumers must receive the required amount of heat, regardless of which control method is used at the heat source, how the heat pipes are designed and what the thermal protection of the building is. In cities and residential areas of Russia, the main consumers of heat energy from district heating systems are heating systems for residential, administrative and public buildings. Industrial facilities also consume heat energy for heating from centralized systems.

Most of the large water heating systems were designed and built in the 1950s-1970s. In heat supply systems for residential areas of cities, for example, the city of Lipetsk and others, in heat supply systems for enterprises, for example, OJSC NLMK, OJSC Svobodny Sokol, the regulation of heat supply is predominantly central and qualitative in terms of heating load. The design schedule for network water temperatures is 150/70 °C, the heating systems of buildings are connected to heating networks according to a hydraulically dependent scheme.

The operating conditions of heat supply systems that have developed in recent years differ significantly from the design ones. The construction of new buildings, the reconstruction of existing ones, both civil and industrial, in most cases goes without a significant reconstruction of the existing engineering life support networks.

Reconstructed and newly built objects are intensively equipped with automated heating points. Equipping buildings and structures with heat supply control points does not exclude central quality regulation, but only supplements it with subscriber regulation. Subscriber regulation, as a rule, provides for either a quantitative or a quantitative-qualitative change in the cost of thermal energy. As a result of the commissioning of such facilities, during the period of outdoor temperatures from the temperature of the beginning of the heating season to the temperature of the break point of the temperature graph, a noticeable change in the consumption of network water occurs in water heating networks. The change in coolant flow rates in the network is the more significant, the higher the proportion of facilities with automated subscriber inputs. Fluctuations in water flow lead to hydraulic misalignment of the water heating network.

The heat balance of the premises must be maintained throughout the entire heating season, and consumers must receive the required amount of heat, regardless of the method of regulation.

Simultaneously with the newly commissioned buildings, the existing heat supply systems provide thermal energy to many buildings and structures in which there is no additional regulation of heat supply by the subscriber. The supply of energy to heating systems during the period of outdoor temperatures above the break point of the graph is carried out by a heat carrier with a temperature exceeding the required values.

The presence of such a conglomerate of facilities connected to a single centralized water heat supply system does not allow centralized cost-effective and energetically justified regulation of heat supply for the heating load of buildings and leads to overspending of heat energy.

In recent years, enterprises that produce thermal energy under the pretext of saving fuel, reducing losses in networks, or for other reasons, have resorted to lowering the estimated temperature of network water. The temperature is lowered from 150 ° C to 140, 130 ° C and lower, both during periods of sharp cooling and during the heating period, that is, they cut the temperature graph or switch to a lower temperature graph. For example, such an enterprise as OJSC Novolipetsk Metallurgical Plant (OJSC NLMK) receives thermal energy from its own CHPP and CHPP Territorial Generating Company No. 4 (TGC-4) and operates according to the temperature schedule 105/70 °C, 130/ 70°C. The Lipetsk Metallurgical Plant Svobodny Sokol receives heat from its own thermal power plant and the boiler house of the Lipetsk City Energy Company (LGEK) (115/70 °C), the Centrolit plant receives heat from an industrial boiler house (115/70 °C). The use of "cutoff" has become more frequent in the last two or three years and is associated with the massive introduction of polymer pipelines in the heating systems of buildings during their reconstruction, as well as new construction. As a result of “cutting off” and switching to a lower temperature graph, the temperature difference of the coolant decreases, which leads to the “undersupply” of the required amount of heat to the heating systems of buildings and structures designed for higher coolant temperatures.

Heat energy suppliers are trying to compensate for the "undersupply" of heat due to a decrease in temperature difference by increasing the flow rate of the coolant by including additional pumping groups in operation. The applied temperature “cutoff” at one or another outdoor temperature is accompanied by a one-time increase in network water consumption for the entire range of outdoor temperatures from the cutoff temperature to the design temperature for heating.

Excessive consumption of water in networks in such cases reaches 40-50% of the design flow. However, it is not always possible to make up for the heat deficit by increasing the flow rate. The increased consumption of network water violates the stable hydraulic regime of the system and leads to misalignment of the heating network. The quality of the heat supplied in such cases differs significantly from the standard. Cutting off the temperature graph shortens the period of time during the heating season when centralized quality control is carried out.

Thus, if the duration of the heating season is about 6 months a year, the central quality regulation is carried out for 2-4 months, and 2-4 months during the heating season fall out of any regulation.

An assessment of the impact of the absence of subscriber additional regulation and temperature “cutoff” on the duration of central quality control during the heating season was carried out for the climatic conditions of the city of Lipetsk using the examples of “cutting off” the temperature graph from 150/70 °C to 130, 115 and 95 °C.

Only for 51.4% of the amount of heat supplied during the entire heating period, central quality control for heating load is applied. 27.6% of the supplied amount of heat is subject to subscriber regulation, or its absence, and 21% are subject to the absence of any regulation as a result of the ongoing “cutting off”.

For “cut-off” conditions from 150/70 °C to 130 °C, 68.9% of the heat supplied during the heating season is subject to central quality control. For “cutoff” from 150 °C to 115 °C - 60.3% and for “cutoff” conditions at 95 °C - 35.8% of the supplied thermal energy.

Thus, if the duration of the heating season is about 6 months a year, the central quality regulation is carried out for two to four months, and two to four months during the heating season fall out of any regulation. The ongoing “cutting off” of the temperature graph with a subsequent increase in the consumption of network water and subscriber adjustment at consumers violate the stable hydraulic regime of heating networks and lead to its misalignment.

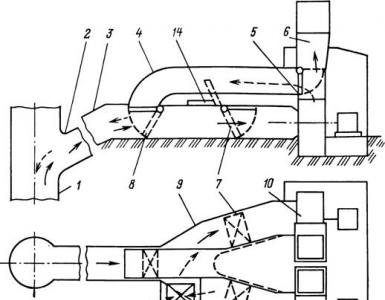

In order to provide buildings and structures with the required amount of thermal energy at current outdoor air temperatures throughout the entire heating season, a method is proposed for supplying consumers with periodic maximum heat supply. The supply of thermal energy to consumers is carried out through several heating mains equipped with shutoff valves.

It is known that the use of the heat storage capacity of buildings makes it possible to regulate the supply of heat for heating not according to the current outdoor temperature, but according to the average value of the outdoor temperature for a certain period, with a corresponding time shift .

The organization of heat supply is based on the unchanging hydraulic regime of the water heating network and on the ability of buildings and structures to accumulate thermal energy.

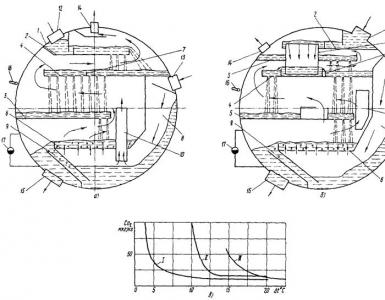

At the heat source there are: a heat-preparation unit, a chilled water collector, where the heat carrier coming from the return pipelines of individual mains is mixed, a hot water collector, and shut-off valves.

The proposed method of heat supply to consumers with periodic maximum heat supply is as follows. The network pump provides a stable hydraulic regime in the entire system. A heat carrier with an increased temperature potential comes from a heat-preparation plant (HPU) into one of the separate lines during a certain (first) estimated period of time. The flow and temperature of the heat carrier are maintained constant, and the flow of network water is sent to the remaining lines, bypassing the heat-preparation plant through the bypass pipeline. The coolant enters other lines and has the temperature of the mixture formed in the chilled water header (CWH). Over time (the first settlement period), the temperature of the mixture will decrease, therefore, the temperature of the indoor air in the heated rooms will decrease. The signal for switching the shutoff valves is the temperature of the internal air at the consumers, and in the next billing period, the coolant is supplied to another area from a source with an elevated temperature, etc.

There is a periodic increase and decrease in the temperature of the coolant in the supply and return pipelines of each of the mains. The system, using the ability of buildings and structures to accumulate and release thermal energy for a certain time, periodically supplies consumers with a slightly overestimated amount of heat.

Thus, there is a periodic increase and decrease in the temperatures of the coolant in the supply and return pipelines of each of the mains. The system, using the ability of buildings and structures to accumulate and release thermal energy for a certain time, periodically supplies consumers with a slightly overestimated amount of heat. In the proposed method of heat supply, a periodic increase and decrease in the temperature of the coolant occurs when heat is supplied through individual heating mains to heat supply areas (TR) with a stable hydrodynamic regime of the system.

The proposed method of heat supply to consumers with periodic maximum heat supply in centralized heat supply systems will create a stable hydraulic regime in water networks and ensure the regulation of heat supply throughout the heating season.

1. Sokolov E.Ya. Heat supply and heat networks. - M .: MEI Publishing House, 2001.

2. Sterligov V.A., Manukovskaya T.G., Loginov V.V., Ermakov O.N., Kramchenkov E.M. The method of supplying thermal energy to consumers in centralized systems. Patent for fig. KI No. 2334173 C1, R24B 3/02 (2006.01).