The nuances of self-installation of a solid fuel boiler

The main advantage of solid fuel boilers is energy autonomy. To work, they do not need anything other than the fuel itself - firewood, peat, sawdust, coal, etc. Installing such a unit is a real way to reduce the cost of heating and hot water supply of a country house, cottage or even a small business. At the same time, you can start saving even at the stage of installation and connection, simply by doing them yourself. But for this you have to take into account that the requirements for the placement, installation and connection of solid fuel boilers differ from the installation standards for gas and electric heat generators. This means that you will have to equip the boiler room, the platform where the equipment will be located, and the piping in a special way.

Basic requirements for the boiler room

Household solid fuel heat generators are installed in separate dry rooms, outbuildings or separate buildings. The dimensions of the boiler room are determined by the dimensions of the unit, as well as the features of its maintenance, however, the smallest allowable area is 7 sq.m. At the same time, it is necessary to provide a place protected from atmospheric influences for storing the fuel supply - it must be dry before loading.

If the walls of the boiler room are made of combustible materials, they must be covered with a 2.5-3 cm layer of plaster or thermal insulation in the form of an 8 mm layer of asbestos and sheet iron. In the absence of fire protection of the ceiling, the distance from it to the boiler body must be at least 120 cm.

The normal operation of a solid fuel boiler is ensured by a stable air supply. Therefore, in the boiler room it is necessary to perform supply and exhaust ventilation. The channel of the first with dimensions of 30x30 cm should go to the lower part of the wall opposite the chimney, and the exhaust hole, the dimensions of which should be 40x40 cm, is located no more than 40 cm from the ceiling. The ventilation of the boiler room must provide normal draft. With its lack, the performance of the boiler decreases, and with an excess, it becomes difficult to regulate the process of fuel combustion.

The solid fuel boiler must be installed on a strictly horizontal fireproof (concrete or brick) platform with a thickness of about 7 cm. On a wooden floor, such equipment can only be installed with an intermediate brick layer covered with a 3-4 mm metal sheet or at least 5 cm cement screed . The base of the solid fuel boiler should be 10-20 cm wider than the external dimensions of the body, but the sides of the firebox should additionally be equipped with a safety zone with a width of at least 40 cm.

Installation standards

Requirements for the installation of solid fuel heating boilers are regulated by the Fire Safety Regulations (NPB) and Building Regulations (SNiP). It is very important to follow the provisions of these regulatory documents, since not only the efficiency of the heating system being equipped, but also the safety of the residents of your home directly depends on this.

Basic standards for the installation of solid fuel boilers:

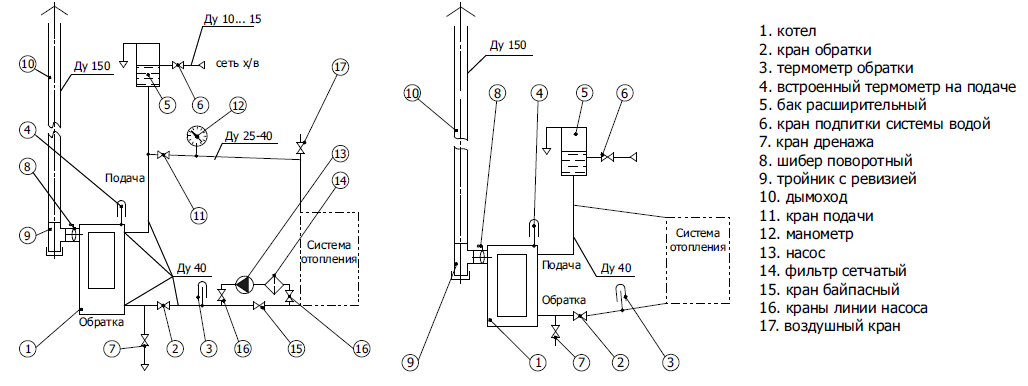

Connecting a solid fuel boiler from various angles in the photo

What do you need to install a solid fuel boiler with your own hands?

If you are not going to involve specialists for the installation of a solid fuel boiler, you will have to prepare for work yourself.

First of all, you will need overalls and tools:

To connect the boiler to the heating system, you must additionally purchase:

The most important thing when installing a heat generator is to follow the manufacturer's instructions. Before starting installation work, it is necessary to assemble the heating system and check it for leaks, as well as organize ventilation and smoke exhaust systems in the boiler room.

Heating systems based on solid fuel boilers should be equipped with open expansion tanks, the function of which is to protect communications from breaking due to overheating of the coolant.

The subtleties of installing solid fuel boilers

The boiler piping scheme is adopted in accordance with the characteristics of the heated object.

It can be implemented using one of the following options:

- boiler in an open heating system with natural circulation and radiators;

- boiler in a closed system with forced circulation and radiators;

- boiler with thermal accumulator in a closed forced system with radiators;

- boiler with a thermal accumulator in a closed system with forced circulation and underfloor heating;

- boiler with radiators and underfloor heating as part of a forced circulation system.

The piping of a solid fuel boiler must be equipped with a security system. The latter includes:

- thermal accumulator or buffer tank;

- three-way valve for mixing cold water;

- thermostat in the control system.

The safety group of a solid fuel boiler is installed at the outlet, i.e. on the hot water line.

Immediately before installing the solid fuel boiler, it is necessary to carry out its visual inspection and test firing in the open air for about 1 hour at the maximum load of the combustion chamber.

According to the requirements of SNiP, after connecting the boiler, a hydraulic test of the system under pressure with a holding time of 24 hours should be carried out.

For this you need:

- connect water, open all taps and valves;

- raise the pressure in the system to 1.3 atm (control valve);

- make sure that there are no leaks, especially in the places of welded and threaded connections.

If the installation, piping and connection of the boiler are performed correctly, there will be no pressure loss and no leakage of the coolant. In this case, you can proceed to the revision of the boiler itself:

First start of the heating system

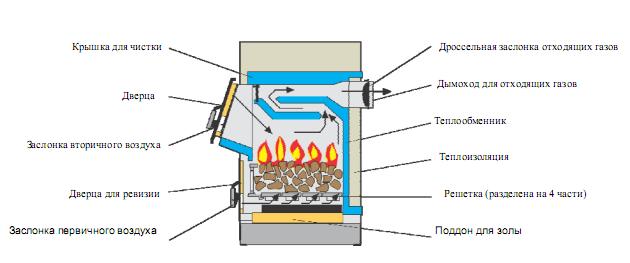

Before the first kindling of the boiler, the pressure in the system should be about 1 atm. Don't forget to open the damper on the chimney. The kindling material is placed on the grate, after which fuel can be loaded into the combustion chamber. After 10-15 minutes from the moment of ignition, the ignition damper should be closed. When the temperature of the coolant in the system reaches 85 ° C, you should adjust the thermostat, and then set the minimum (about 5 cm) gap between the primary damper and the furnace door.

Installing a solid fuel boiler is not an easy task, but it is quite solvable. It is important not only to comply with the requirements of regulatory documents, but also to follow elementary logic. And do not forget to use the successful experience of those who have already dealt with the organization of heating systems based on solid fuel heat generators. The most important thing is to ensure the optimal operation of the heating equipment. After all, its reliability and durability and, of course, the microclimate in the premises of your home directly depend on this.